Project Experience

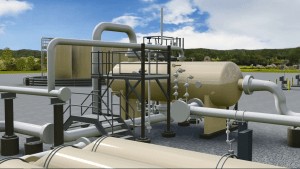

De-Ethanizer Storage Facility

Borton-Lawson completed this fast track project to install a new 150,000 gallon de-ethanizer storage vessel into an existing process facility in the Marcellus shale play, West Virginia. The existing facility needed to stay in service without interruption throughout the duration of the project. The vessel was delivered to the site and installed per plan, keeping the facility in operation while meeting schedule.